Postion: Home > Our Case > Welding Services >

We empoys experienced welders, certified welders and robotic welders. This combination of expertise and accruacy ensure us that we can consistently provide you with world-class qualified welded parts. From simple spot-welds to complex assemblies, we can produce quality weldments in aluminum, carbon steel, stainless steel, and brass.

We welcome all welding metal fabrication orders, from smal, single part orders to large assemblies and multiple run parts. Whether it is just few pieces or it is a full container, we take the responsibility.

After cutting metal pieces to desired sizes, it is necessary to join them to suit desired shape and specifications. So, sheet metal welding is an important aspect of metal fabrication.

If you're looking for a reliable, high-quality sheet metal welding service that you can trust, look no further than our factory. Contact us today to learn more about our capabilities and how we can help you achieve your welding goals.

6 Methods of Sheet Metal Welding

1. MIG Welding

MIG welding is an arc welding process in which a continuous solid wire electrode is fed through a welding gun and into the weld pool, joining the two base materials together. A shielding gas is also sent through the welding gun and protects the weld pool from contamination. In fact, MIG stands for metal inert gas. The technical name for it is gas metal arc welding (or GMAW), and the slang name for it is wire welding.

MIG welding creates top-quality welds, and itŌĆÖs suitable for most sheet metals, such as aluminum, steel, and stainless steel.

This welding method is the go-to technique in the automotive and home improvement industry. Also, it is a cost-effective technique, as it requires no sophisticated machines.

TIG Welding

Tungsten inert gas welding (TIG), also frequently referred to as gas tungsten arc welding (GTAW), uses a tungsten electrode to create the electrical arc which makes the weld. Unlike the electrode in MIG welding, the tungsten electrode is not consumable and does not melt to form part of the weld. TIG welding is a slightly more complex process and is ideal for thinner gauge metals.

TIG welding is suitable for welding non-ferrous metals like aluminum, titanium, copper, nickel, magnesium, chromium, etc. It is a valuable technique for the aviation and aerospace industries. Also, it is ideal for fabricating frames for motorcycles, doors, and feeders.

This welding method provides the welder with better control leading to a neat and strong weld. However, it may be time-consuming and requires expertise on the part of the welder.

Stick Welding

SMAW (Shielded Metal Arc Welding), also called stick welding is the most commonly used welding approach in all arc welding procedures. To join various metals, it utilizes an electric current and an anode at the weld pool.

Its versatility and simplicity makes it more popular. The anode consists of a stick or solid metal stick (therefore the name) encircled by a covering of metal powders and composites with an agent that binds them so that they can fasten to its surface.

Remember that the correct term for the rod is an electrode. The electric current (AC or DC) is used to produce an electric arc between the metals youŌĆÖre attaching and the electrode. This spot is known as the weld pool.

Stick welding is mainly used in welding steel and iron and is widely used in the repair and maintenance industries, as well as in the construction of heavy steel structures.

Plasma Arc Welding

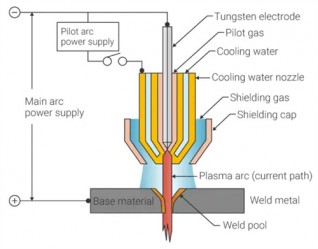

Plasma welding is a welding method that uses a plasma arc. Plasma welding is a method that strikes a plasma arc between the electrode and base material and uses it for welding. It is classified as a non-consumable electrode type and, as with TIG welding, it uses a tungsten rod for the electrode. The difference is that it uses a nozzle to cover the electrode and a plasma gas to prevent the arc from spreading.

The resulting high heat concentration enables high-speed welding with a narrow bead and less distortion. Due to its highly directional arc, plasma welding is suitable for fillet welds and can eliminate spatter. Its low electrode consumption allows high-quality welding for a long time. Although the welding machines are expensive compared to TIG welding machines, the running costs are low. This is one of the best methods for automatic welding.

The pilot gas (inert gas) passes through the torch and is ionized by the pilot arc heat (plasma conversion). The ionized pilot gas forms a plasma jet, spouts from the nozzle hole and acts as the conductor for the arc current. This narrows down the arc to give it high energy density and spout from the insert tip hole. The spread of the arc is limited to about one-fourth that of TIG welding, resulting in an arc with higher current density.

Electron Beam and Laser Welding

Gas Welding

Gas welding is one of the traditional forms of welding by heat. It involves using heat generated from burning fuel (gasoline), oxygen, or oxyacetylene to join pieces of metals together. The burning of these fuels produced very hot flames that melt metal surfaces during joining.

It is one of the oldest forms of heat-based welding and remains the go-to option for many industries. It has a broad scope of application, suitable for both ferrous and non-ferrous metals. Also, it is effective and efficient for welding pipes and tubes, repairs of ventilation and air conditioning systems, etc.

Unlike many other welding techniques, it doesnŌĆÖt require electricity. Also, it is portable, highly economical, and doesnŌĆÖt require the services of specialists.