Postion: Home > Our Case > Stamping & Bending >

Why Choose Our Sheet Metal Stamping Parts?

ŌŚÅ Manufacture to Specification: We work directly from customer drawings to produce precise sheet metal parts, ensuring every detail matches your requirements.

ŌŚÅ Feedback on Drawings: If we identify potential issues in the provided designs, such as feasibility or cost concerns, we will notify you and offer suggestions to optimize the production process.

ŌŚÅ Wide Range of Materials: We work with various metals including stainless steel, aluminum, and brass, allowing us to create durable and corrosion-resistant parts.

Key Applications for Sheet Metal Stamping Parts:

ŌŚÅ Automotive: Brackets, clamps, and structural components for vehicles.

ŌŚÅ Electronics: Enclosures, heat sinks, and connectors for electronic devices.

ŌŚÅ Home Appliances: Precision components for durable and functional household products.

Our Process:

1.Customer Drawing Review: We analyze the provided drawings and point out any potential production issues.

2.Production & Quality Control: Using advanced metal stamping technology, we ensure all parts are manufactured to high precision.

3.Timely Delivery: Efficient production allows us to meet deadlines while maintaining strict quality standards.

Image Descriptions:

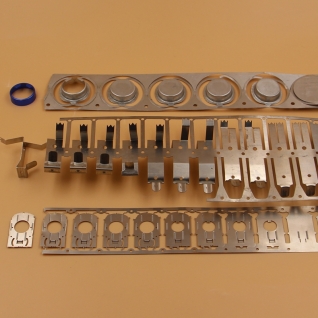

1.Sheet Metal Brackets

Precision sheet metal brackets created from customer designs.

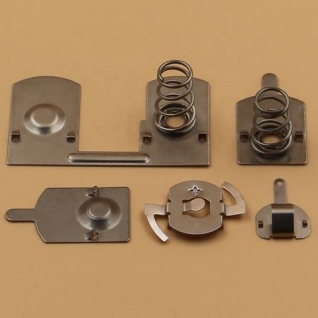

2.Stamped Metal Components

Custom stamped components, produced directly from customer-provided drawings.