Postion: Home > Our Case > Case Studies >

CATEGORIES

CATEGORIESLooking for high-quality custom sheet metal prototype fabrication? At Hongming Sheng, we specialize in bringing your designs to life with precision, speed, and reliability.

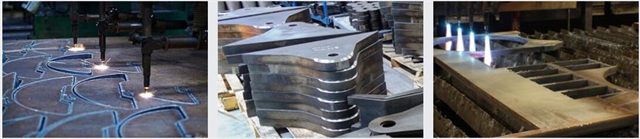

With cutting-edge equipment and years of expertise, we deliver functional and visually appealing prototypes. From laser cutting to welding and CNC machining, every part of our process meets high performance and aesthetic standards.

Get Your 30 Second Quote NowOver 200,000 quotes provided to top China companies.

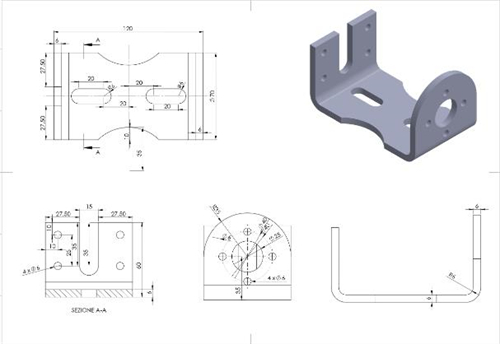

A sheet metal prototype is a tangible version of your design that allows you to validate function, form, and manufacturability before moving to mass production. It helps attract investors and ensures product readiness.

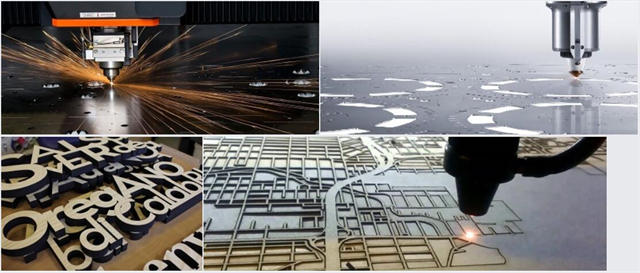

High-precision fiber laser cutting ensures clean edges and tight tolerances (±0.15mm), ideal for prototyping complex geometries.

Cold cutting without thermal distortion, perfect for maintaining material integrity.

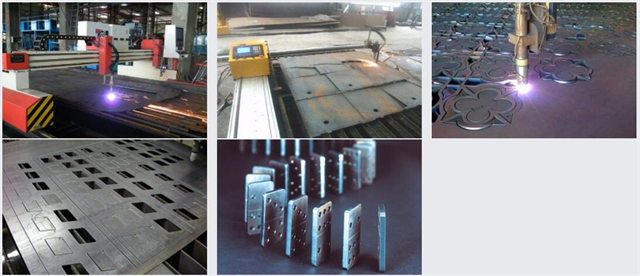

Ideal for producing high volumes of consistent metal parts—brackets, clips, enclosures, and more.

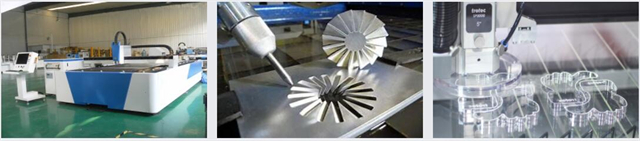

From 3-axis to 5-axis, CNC ensures tight tolerance and precision prototyping in both plastic and metal.

High-precision chemical etching offers fast and economical production from prototype to full scale.

Services include TIG, MIG, spot, laser, and arc welding—ideal for robust assembly.

Removes burrs, improves surface finish, and enhances appearance before finishing.

Protects parts from corrosion and improves aesthetics—options include anodizing, powder coating, painting, and polishing.

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | Precision CNC Machining / CNC Milling Services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Surface Finishing | Sheet Metal Enclosures Housing Box And Case Fabrications |