Postion: Home > Our Service >

Our Service

Our ServiceNon-Disclosure Agreement

Hongming sheng always respects the rights of intellectual property rights and opposes any plagiarism or counterfeiting. Without the approval of the customer, we cannot disclose any relevant information to a third party, including but not limited to product drawings, design plans, product pictures, molds, manufacturing processes, etc. Hongming sheng is willing to sign NDA with customers to protect the interests of both parties.

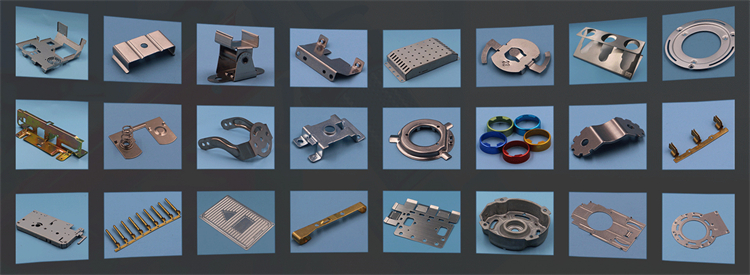

With excellent metal stamping capacities,HONGMING SHENG provide services to clients with competitive costs and top notch stamping products. We provide a wide scope of metal stamping services, for example, single stamping, progressive die stamping,in-die tapping, composite die stamping, etc and so on.

As a professional metal stamping company, we have been focused on metal stamping manufacturing for 11 Years, understand the requirements of every industry for stamping items, kindly let us know how to utilize the product and the business and reference standard, with we will give you a detailed product design and production plan report before getting the metal stamping dies.

HONGMING SHENG equipped with independent focal point of the metal stamping dies, The stamping products was set up with UG software, like the model, the utilization of CNC machining and grinding polishing cleaning process, get the metal stamping dies, in a usual routine cycle of 12 days, the structure iis extremely complicated stamping parts of the dies up to 30 days.

HONGMING SHENG can develop different types of metal stamping dies, and can be proficiently fabricated and placed into production. Ensure the design metal stamping dies, meets the most severe stamping specifications.We can produce 84 x 144 long progreissive die.Our specialty is creating imaginative solutions for a scope of component materials including high strength steel, hardened steel and aluminum.

Precision metal stamping is widely used by sheet metal stamping services . It is characterised by the minimal expense and high-effectiveness large scale processing. The sheet metal stamping company can keep up with stable superior quality and progress, and customised production as indicated by your requirements and resilience ranges.

Precision metal stamping is an assembling strategy processed by the sheet metal stamping company, it is used to transform sheets of metal into the ideal size and shape of the parts required for different industries. This process enables quick and precise production of a wide range of metal parts by varied operations of sheet metal stamping company, for example, stamping ,folding, drawing and piercing into a single operation or series of associated tasks.

In addition to higher accuracy and exactness, the other benefits our precision sheet metal stamping services exhibits over other assembling measures by competitors of sheet metal stamping china industry, include:

Greater process and better product quality. Precision presented by the sheet metal stamping services means making less mistakes during production . This implies there is less chance of producing mistakes or making it under the control of clients and sheet metal stamping companies .

Lower production costs. For the most automated process under sheet metal stamping services, mitigates the requirement for manual labor work. This quality leads in a lower mistake rate, which also means less material usage and waste during a production run of a sheet metal stamping company.

Progressive Die Stamping Services

It is a high-efficiency metal stamping services. The progressive die stamping mold has multiple stations, and each station will perform different stamping steps, such as: cutting, bending, hole, rolling, stamping LOGO, etc. It has the characteristics of high production efficiency, lower cost, higher repeatability, and higher precision. The technical cost of the mold is relatively high, which is suitable for the rapid production of mass products.

The decision to produce a part in progressive stamping dies upon size, intricacy and volume of production. Progressive stamping die is a type of metal stamping dies, utilized to produce an enormous number of parts and keep the expenses as low as could really be expected. The greatest levels of demands in accuracy and durability should be met.

Because of the intricacy of progressive stamping dies, your trusted metal stamping company of HONGMING SHENG will deal with all factors that contribute to accomplishing the ideality of part quality, including blank position, pilots, limits and boundaries and stretch-web deformation.

Pilots assume a significant role in progressive stamping – they fix the strip into a proper position and keep up with power over it. Likewise, they are fundamental for precise sheet positioning during apparatus closing and attracting tasks that kick the bucket. Different components to be considered are timing and collaboration of transporters, pads, and upper and lower tools. The advantages of progressive stamping are expanded usefulness and tremendous expense decrease for high-volume production.

At Hongming Sheng, rigorous quality control is at the heart of our manufacturing philosophy. Every phase, from material sourcing to final shipping, is carefully managed to guarantee the delivery of premium-quality sheet metal stamping parts to our valued customers.

We collaborate with established steel mills, performing thorough chemical and physical inspections on all raw materials. Each batch includes a certified material verification before storage, ensuring consistent material quality.

Our specialists carefully inspect material dimensions prior to processing. This step prevents potential issues such as material waste or insufficient machining allowances, ensuring accuracy from the outset.

Through meticulous production planning, workflow optimization, and strict time management, we effectively control every stage of manufacturing, ensuring timely completion and delivery of metal stamping orders.

Continuous dimensional inspections throughout production enable early identification and resolution of potential quality concerns, maintaining consistently high standards.

Comprehensive inspections are conducted post-production, accompanied by detailed reports verifying compliance with precise customer specifications.

Each finished component is meticulously inspected for surface defects such as scratches, dents, and improper finishes. Functional assembly tests ensure parts perform reliably in their intended applications, delivering excellence in every aspect of our sheet metal stamping services.

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Sheet Metal Fabrication Services | Precision CNC Machining / CNC Milling Services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Metal Stamping Services | Surface Finishing | Sheet Metal Enclosures Housing Box And Case Fabrications |