Postion: Home > Our Case > Metal Fabrication >

CATEGORIES

CATEGORIESLooking to turn your concept into a precise metal product? At Hongmingsheng, we specialize in customized sheet metal prototype manufacturing to help global clients validate and refine their designs before mass production. Whether you're in the early R&D phase or ready for small-batch manufacturing, our team offers one-stop fabrication support—designed to meet tight tolerances and fast lead times.

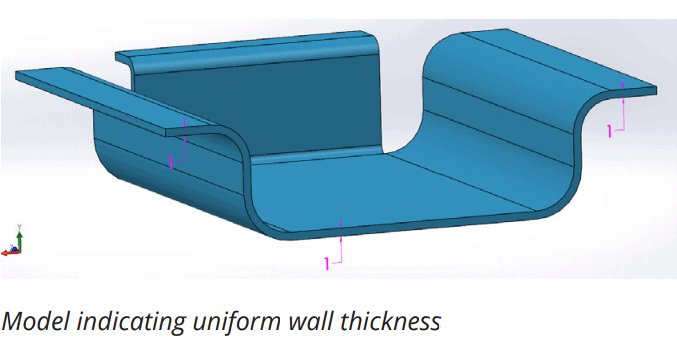

Our process begins with your idea or sketch. We help develop engineering drawings and 3D models, perform manufacturability analysis, and produce working prototypes using processes like sheet metal fabrication, cutting, and bending.

Our expert engineers ensure high-precision bends through proper design clearances, bend radii, and part orientation. We also offer guidance for slots, hems, curls, and notches to prevent deformation.

If you're ready to bring your prototype to life with a reliable Chinese factory, submit your drawings for an online quote or contact our team directly at info@hms1688.com.

Let us help turn your prototype into production—quickly, professionally, and precisely.

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | Precision CNC Machining / CNC Milling Services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Surface Finishing | Sheet Metal Enclosures Housing Box And Case Fabrications |